IBD partners with Ugandan start-up Takataka Plastics

Over the past 29 years of the IBD program, it has been rare for an IBD project client to be a co-founder of an international start-up and a UC Berkeley student at the same time. This year the Berkeley Haas IBD program is collaborating on an exciting sustainability project with Takataka Plastics, a start-up located in Gulu, Uganda. Takataka Plastics was launched in January 2020 by Peter Okwoko and Paige Balcom, who is working on her UC Berkeley PhD in Mechanical Engineering, with an emphasis in Development Engineering. IBD interviewed Paige and Peter about how they developed Takataka Plastics, why they wanted help from the IBD program, and what they hope to get out of the partnership.

IBD Interviewer: Tell us more about yourselves. What are your backgrounds?

Takataka Plastics, Paige Balcom:

Before starting graduate school, I spent a year in Uganda on a Fulbright research grant. I worked with an NGO that runs a vocational school for child mothers in a little village outside of Gulu, Uganda, to build a couple of aquaponic systems for their farm. I learned a lot about the challenges of engineering in an off-grid rural village, but even more importantly, I experienced the rich culture of Uganda, the challenges millions of Ugandans face in their daily lives, and the simple joys of living in the community.

When I started graduate school at Berkeley, I told my advisor I wanted to do research in Uganda to help address some of the challenges my new friends faced. I started researching plastic waste in Uganda. I applied to the Big Ideas competition, won some funding, and went back to Uganda to conduct field work where I met Peter, who was already working on waste management in Gulu.

Takataka Plastics, Peter Okwoko:

I spent most of my childhood in Eastern Uganda, and in 2009 I returned to Northern Uganda to pursue my Degree in Information and Communications Technology at Gulu University and a post graduate diploma in project planning and management. After that program I was appointed a graduate trainee at the Department of Computer Science. This opportunity gave me an understanding of the depth of the challenges that students go through in Ugandan universities. In 2015 I received a Danida Fellowship to pursue a MSc in Innovative Communication Technologies and Entrepreneurship at Aalborg University in Denmark. I was fascinated by how Danish cities are so clean. I learned about various methods deployed to maintain urban areas. This inspired me to start up a waste management venture called Afrigreen Sustain in Uganda during the summer of 2016. At the same time, I informally started a local initiative with a few friends called Hashtag Gulu to support street connected youth. After completing my masters, I returned to Uganda and resumed teaching at Gulu University while running Afrigreen Sustain and also volunteering with Hashtag Gulu. I then met Paige and we started Takataka Plastics.

IBD Interviewer: Why did you co-found Takataka Plastics?

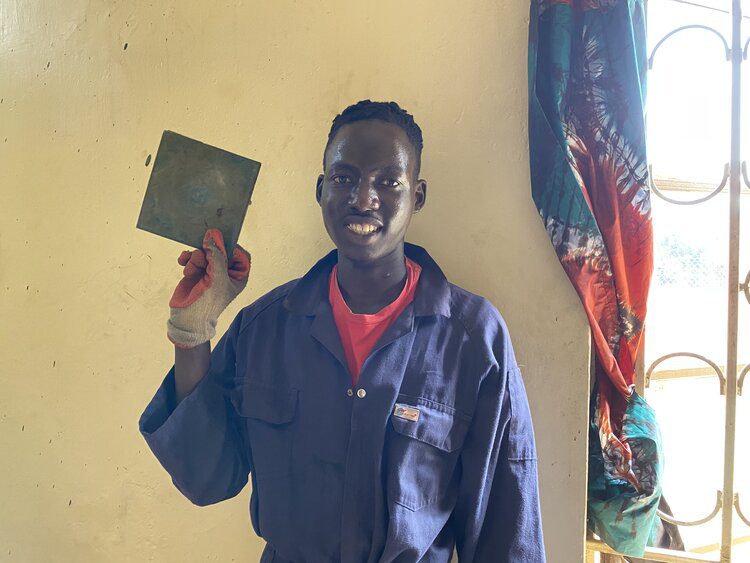

Takataka Plastics: We founded Takataka Plastics to create jobs, especially for street-connected youth, and recycle plastic waste to care for the environment and improve public health. Our motto is “transform waste and empower communities.”

After years of research and experimentation, we realized there is a need for local recycling outside of the capital, and Uganda is “desperate for a solution to PET” plastic because the country currently has no way of recycling water and soda bottles. Uganda produces 600 tons of plastic waste every day, and 87% is burned or dumped in roads, open land and waterways. In Gulu, where we work, nearly all the PET is burned or dumped because transporting empty bottles six hours to the capital isn’t profitable.

We developed small-scale, low-cost, primarily locally made machines that can safely transform plastic waste into construction materials—and we developed a process to do it with PET. We’re making wall tiles for washrooms and kitchens from PET plastic waste. We launched Takataka Plastics with the goal of recycling nine tonnes of PET per month in Gulu (approximately half of the city’s plastic waste), but when the COVID-19 pandemic struck, we temporarily shifted production to manufacturing reusable face shields from plastic waste. Over six months, we produced and distributed over 10,000 face shields to health facilities and schools in 27 districts across Uganda.

IBD Interviewer: What are you most proud of?

Takataka Plastics:

We’re most proud of the impact we’ve been able to have on the lives of our staff. We currently have 14 full-time employees, six of whom are former street youth. A steady job with good pay, a supportive work environment, savings groups, and trauma counselling has changed their lives.

IBD Interviewer: Why did you want to partner with the IBD program?

Takataka Plastics:

We wanted to work with IBD because of the great skills the students and faculty advisors bring. Neither of us have business backgrounds, so we need guidance to grow and strengthen Takataka Plastics. We essentially get four exceptional Berkeley Haas MBA students to work for us as consultants for a semester on a challenging project, and we get to learn from them along the way.

IBD Interviewer: What do you hope to get out of the IBD experience?

Takataka Plastics:

We hope our IBD team will help us create a five year expansion plan to map out how we can scale as a self-sustainable business. Our IBD team will be looking at products, market fits, business planning, and financial modeling. We’re hoping to learn a lot from our team along the way about business strategy.

IBD Interviewer: We know it is still early in the spring semester IBD class, but do you have any thoughts about your IBD team and what they bring to the project?

Takataka Plastics:

We’re really impressed by the wealth of experiences and knowledge our team brings, their enthusiasm and dedication, and their professionalism. We’ve only had a couple of meetings so far, but we already love working with our IBD team! They offer a lot of valuable insights and strategic advice, and their well-organized communication and structure makes working with them a pleasure.

IBD Interviewer: Is there anything else you’d like us to know about Takataka Plastics and the sponsorship of your first IBD consulting project?

Takataka Plastics:

We believe Takataka Plastics’ business model and engineering innovations have the potential to make great impacts in the world. If we could scale to all developing nations, we’d create over 700,000 production jobs for vulnerable youth and recycle two billion kg of plastic waste annually.

We’re extremely grateful to work with our talented IBD team in this respected program to help guide us in achieving those goals. As a young social enterprise, we’re looking forward to learning and benefiting a lot from the Berkeley Haas MBA students’ strategic business advice.

End of the Interview

To learn more about Takataka Plastics, check out their website and Facebook page and blog.

To follow the impact of Takataka Plastics on the spring semester 2021 IBD program, please continue to check this blog.